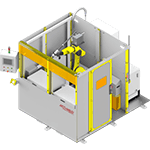

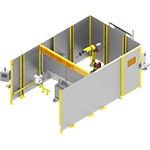

The rotary table allows the operator to load/unload the product outside of the weld cell, then the rotary table will bring the product into the cell for welding. When the robot has completed the welds on side “A” it will rotate table and begin welding side “B”