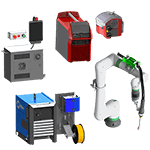

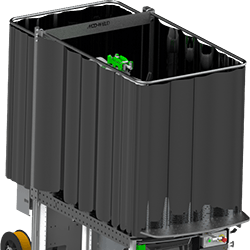

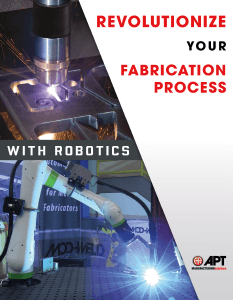

The MOD-WELD is designed and manufactured exclusively around the FANUC CRX-10iA/L industrial collaborative robot. The CRX models come from a long line of reliable FANUC products that are extremely easy to setup, program, and operate – even if it’s your first robot.

You pick the choice of power supply: Miller Auto-continuum or Fronius TPS/i.

Menu

- wrapper

- Robotic Palletizing

- Robotic Cutting & Welding

- Industrial Education Solutions