Menu

MTEC w/ FANUC CRX Cobot

MTEC w/ FANUC LR Mate Robot

FANUC Robotics Courses:

CNC Concepts Courses:

APT Integration Courses:

Career Paths:

NOCTI Certifications:

NIMS Certifications:

Material Handling (MH) CERT Instructor Training and Tool Kit

Material Handling (MH) CERT School Comprehensive Educational Package

*FANUC Education Grant available for new Educational Institutes. Work with reseller to confirm details.

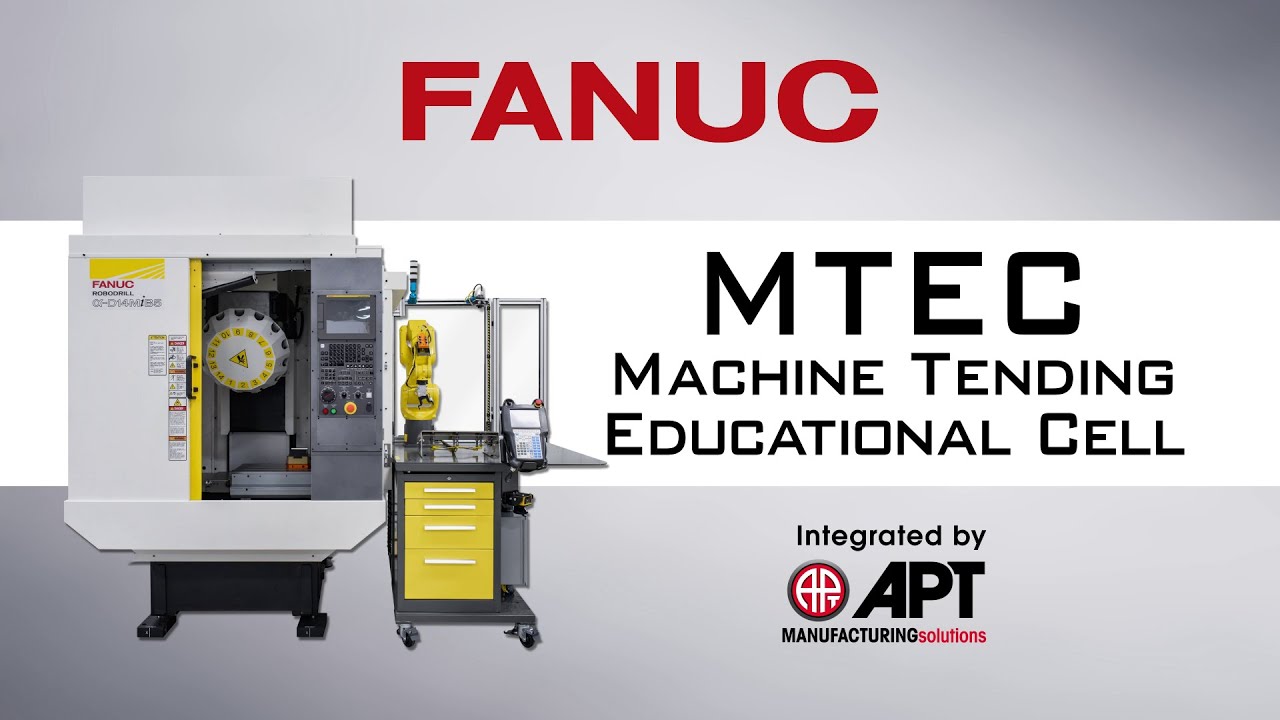

FANUC LR Mate 200iD/7L long-arm 6-axis robot with R30iB Plus robot controller

OR FANUC CRX-10iA collaborative 6 Axis robot with R30iB Mini Plus robot controller

2D iRVision Optional

FANUC’s new R-30iB Plus Robot Controllers feature the new iPendant with enhanced screen resolution and processing capability. The new user interface, iHMI, can display guides for setup and programming, as well as tutorials from the main home page which has a design common to FANUC CNCs, enabling easier use of robots. Using the programming guide, even first-time robot users can create a program for a simple handling task and execute it in just 30 minutes! Easier usage also improves efficiency by facilitating system setup and maintenance.

FANUC’s CNC certification is an industry certification We offer many options for the student to obtain this certification. The FANUC ROBODRILL and simulators along with any CNC machine that has the FANUC controls. FANUC offers the school instructor FANUC training, they can also use the FANUC approved curriculum.

There is a letter issued to the student upon completion to say they are certified. For the instructor there is a certificate template that can use to issue the student certificates.

CNC Mill Work Holding Kit Includes:

Starter Kit for BT30 Robodrills Machines (Includes 1 each):

Options:

Weld CERT Cart