Menu

FANUC Robotics Courses:

Rockwell Automation Courses:

APT Integration Courses:

Career Paths:

NOCTI Certifications:

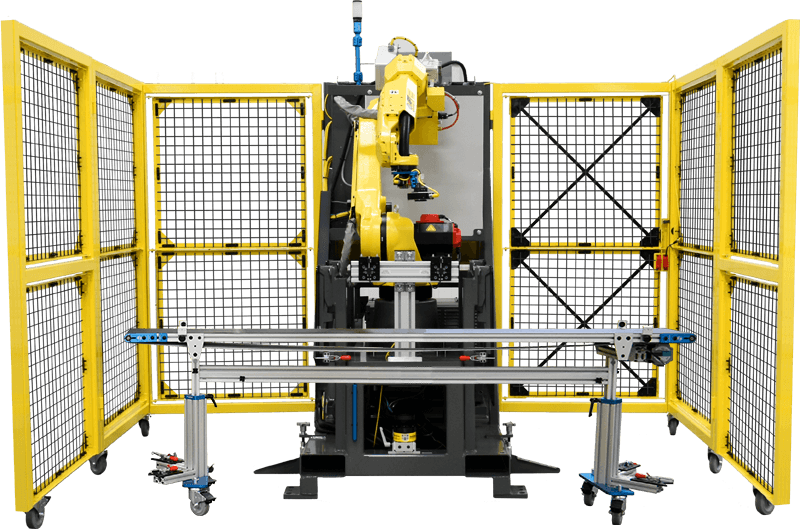

Material Handling (MH) CERT Instructor Training and Tool Kit

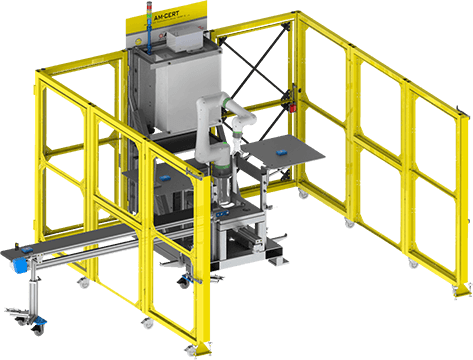

Material Handling (MH) CERT School Comprehensive Educational Package

*FANUC Education Grant available for new Educational Institutes. Work with reseller to confirm details.

Software

Rockwell Automation EDU Toolkit Bundle

Curriculum

Learning+ course content

Available through your local Rockwell distributor.

FANUC M10iD or M20iA 6-axis robot

FANUC CRX-10iA 6 Axis robot

Optional 2D iRVision Available

FANUC’s new R30iB Plus robot controllers feature the new iPendant with enhanced screen resolution and processing capability.

The new user interface, iHMI, can display guides for setup and programming, as well as tutorials from the main home page which as a design common to FANUC CNCs, enabling easier use of robots.

Weld CERT Cart