- CNC Programming

- G-Codes & M-Codes

- Speeds & Feeds

- Set-up Tooling & Vise

This welding cart is designed with specifically FANUC ARC Mate robots and FANUC CRX cobots in mind. You can choose a power supply from either Miller or Fronius. The system comes pre-loaded with Touch Sensing & Through-Arc Seam Track.

This welding cart is designed with specifically FANUC ARC Mate robots and FANUC CRX cobots in mind.

You can choose a power supply from either Miller or Fronius. The system comes pre-loaded with Touch Sensing & Through-Arc Seam Track.

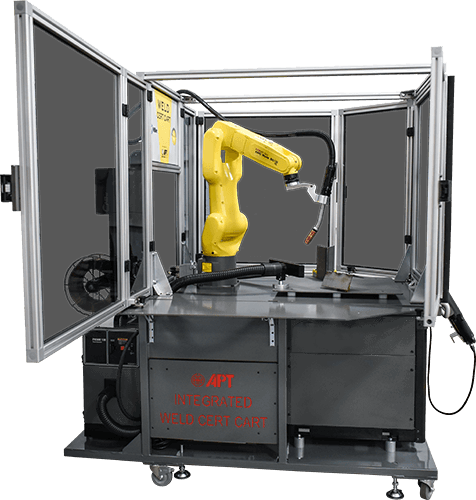

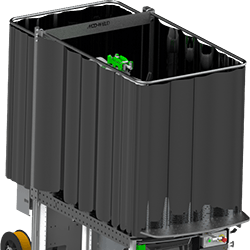

This welding cart is specifically designed for the FANUC ARCMate 50 Robot. FANUC is the most used robot in the industry due to its reliability & advanced control system. The cart features safety switches, is enclosed with tinted glass, and has wings that fold down to fit through a 36” door. While in teach mode, it allows students to work from either side or the front, thanks to it’s three access doors. You can choose a power supply from either Miller or Fronius. The system comes pre-loaded with Touch Sensing & Through‑Arc Seam Track.

FANUC ARCMate 50 Robot, Cart, Fixture Table, Miller Auto-continuum/Deltaweld or Fronius TPS/i Power Supply Choice, and torch along with pre-loaded FANUC software. (Through-Arc Seam Track not available on Deltaweld)

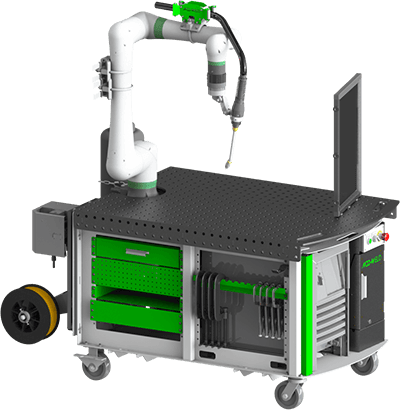

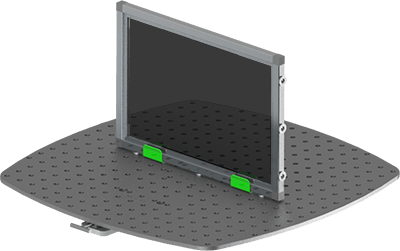

This welding cart is designed exclusively around the FANUC CRX-10iA Cobot. The student can program using the FANUC drag-and-drop features on the tablet and move the cobot by hand into different positions. The cart comes with 16mm fixture holes on 2” centers. You can choose from Miller or Fronius power supplies.

The system comes pre-loaded with Touch Sensing & Through‑Arc Seam Track.

FANUC CRX-10iA, cart, Fixture Table, Miller Auto-continuum/Deltaweld or Fronius TPS/i Power Supply Choice, and torch along with pre-loaded FANUC software. (Through-Arc Seam Track not available on Deltaweld)

Fronius TPS/i, air-cooled torch for welding steel. Comes with .035 wire feed rollers 3PH Power & PMC Software. Optional consumable or replacement parts up to 1/16

Miller Auto-Continuum™ 3PH or Auto Deltaweld™ 1PH, air-cooled torch for welding steel. Comes with .035 wire feed rollers. Optional consumable or replacement parts up to 1/16

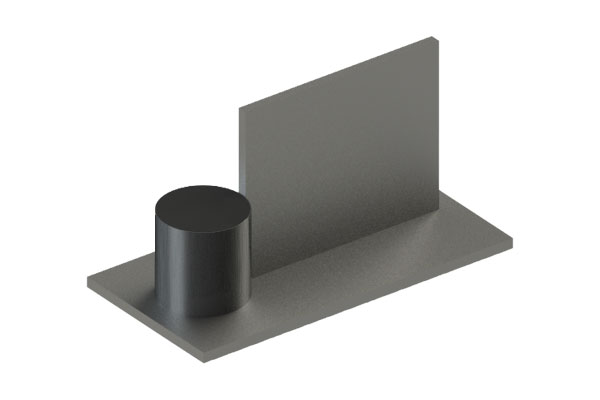

This kit provides all the necessary materials to perform AWS CRAW (Certified Robotic Arc Welding) test. Components will work with either the ARC‑Mate 50 or the Cobot MOD‑WELD cart.

Includes: 10 sets of materials that includes bottom plate, vertical plate & solid round

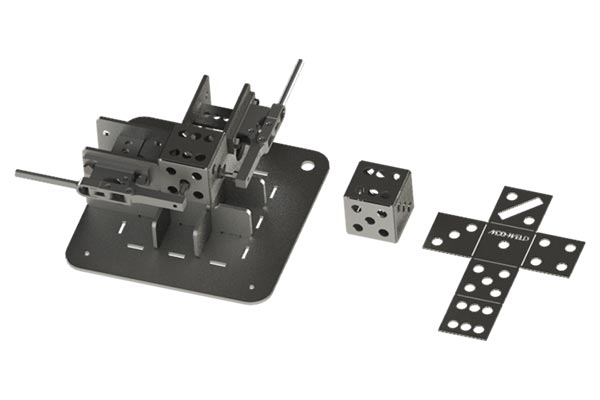

This versatile project allows students to retain their kits throughout their entire welding journey. They create their own fixtures using the supplied components. The dice coupons are excellent for practicing hand, MIG, TIG, & robotic welding. The challenges posed by outside corners and thin sheet metal enhance their skills. Each dice cube features 12 seams, enabling 30 inches of welding.

Includes:

See below for full details

Material to run additional welding dice coupons

Includes: (10) Dice coupon blanks

These accessories are exclusive to the Fenceless Cobot Weld Cart and are not compatible with the Fenced Traditional Robot Weld Cart.

Add up to 4 sides to your cobot cart in different configurations for customizing your work space.

| Image1 / Part#1 | Description 1 | Image2 / Part#2 | Description 2 | ||||

|---|---|---|---|---|---|---|---|

| Collaborative Positioners | green | ||||||

| MIT40 | grey | ||||||

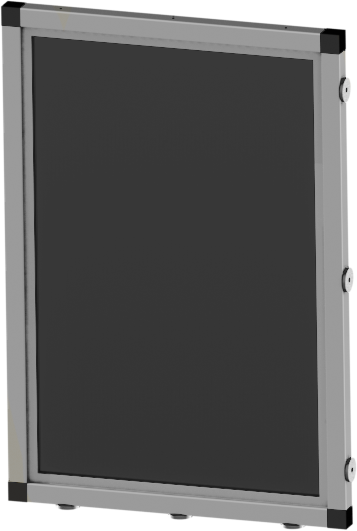

| Collaborative Manual Index Positioner for Collaborative Robot Welding (Shown with WS 1826 Weld Screen)

| ||||||

| Safety | green | ||||||

| PCMC-8 | WS1826 | grey | |||||

| Pull curtain - #8 plastic curtain Where the curtain comes together there are magnets to hold it closed Note: This is a safety shield from arc, not a safety shield from the robot |  | Tabletop Magnet Screen - #8 Dark Shield Mounts in 2 directions, 18" x 26" | ||||

| Drawers and Shelves All drawers have ball bearing slides for smooth function. | green | ||||||

| DW1025 | DW2025 | grey | |||||

| Shallow drawer - Narrow Inner |  | Shallow drawer - Wide Inner Dimensions: 18.8"W x 14.8"L x 2.4"H Locations: B D | ||||

| DW1040 | DW2040 | grey | |||||

| Medium drawer - Narrow Inner Dimensions: 8.8"W x 14.8"L x 3.9"H Location: E |  | Medium drawer - Wide Inner Dimensions: 18.8"W x 14.8"L x 3.9"H Locations: B D | ||||

| DIVS10 | DIVS20 | grey | |||||

| Drawer divider set for narrow drawers |  | Drawer divider set for wide drawers Fits in: DW2025, DW2040 | ||||

| SH1025 | SH2025 | grey | |||||

| Storage shelf - Narrow 10"W x 15.75"L x 2.5"H Locations: E |  | Storage shelf - Wide 20"W x 15.75"L x 2.5"H Locations: E | ||||

| SCSH10 | SCSH20 | grey | |||||

| Spray can storage shelf - Narrow 12"W x 3.625"D Locations: E F |  | Spray can storage shelf - Wide 22"W x 3.625"D Locations: A B C D | ||||

Storage, Bin, Clamps and Pins | green | ||||||

| BINP10 | BINP20 | grey | |||||

| Bin box panel - Narrow, Includes 2 bins Bin size: 4 1/8”W x 5 3/8” L x 3” H Locations: E F |  | Bin box panel - Wide, Includes 4 bins Bin size: 4 1/8”W x 5 3/8” L x 3” H Locations: A B C D | |||||

| CR1007 | CR2013 | grey | |||||

| Clamp Hanger - Narrow 7 clamp notches Locations: E F |  | Clamp Hanger - Wide 13 clamp notches Locations: A B C D | |||||

| PB1006 | PB2006 | grey | |||||

| Pegboard Panel - Narrow Ø.25 holes, 1” spacing, Hole array 10 x 6 Locations: E F |  | Pegboard Panel - Wide Ø.25 holes, 1” spacing, Hole array 20 x 6 Locations: A B C D | |||||

Holders | green | ||||||

| AGHG45 | grey | ||||||

| Angle Grinder Holder with Cord Wrap Fits 4-1/2" Grinder | |||||||

Career Paths:

NOCTI Certifications:

AWS Certifications:

FANUC Robotics Courses:

Miller OpenBook™ Courses:

**Must purchase vision options in order to teach FANUC iRVision

Weld CERT Cart