Menu

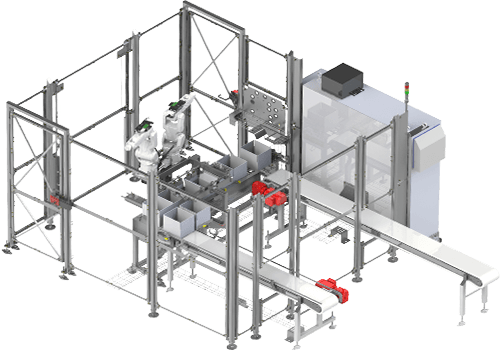

APT is an authorized system integrator exclusive to FANUC America that builds fully integrated systems for packing and palletizing products. These systems are designed to work with upstream and downstream equipment such as: case erectors, case closers, label applicators, and stretch wrap machines.

The robot systems are equipped with a user-friendly HMI/PLC Rockwell operator interface. The cobot CRX25 palletizer has the option of the HMI/PLC operator interface or the use of the tablet. This allows operators, supervisors, or maintenance to quickly navigate the equipment on the floor.

Integrated with:

Frame Options:

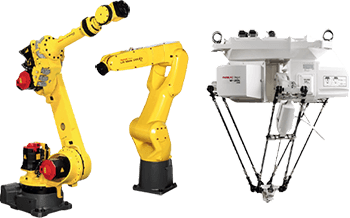

FANUC Palletizing Robots:

FANUC Packaging Robots:

FANUC High Speed Pick Pack Robots:

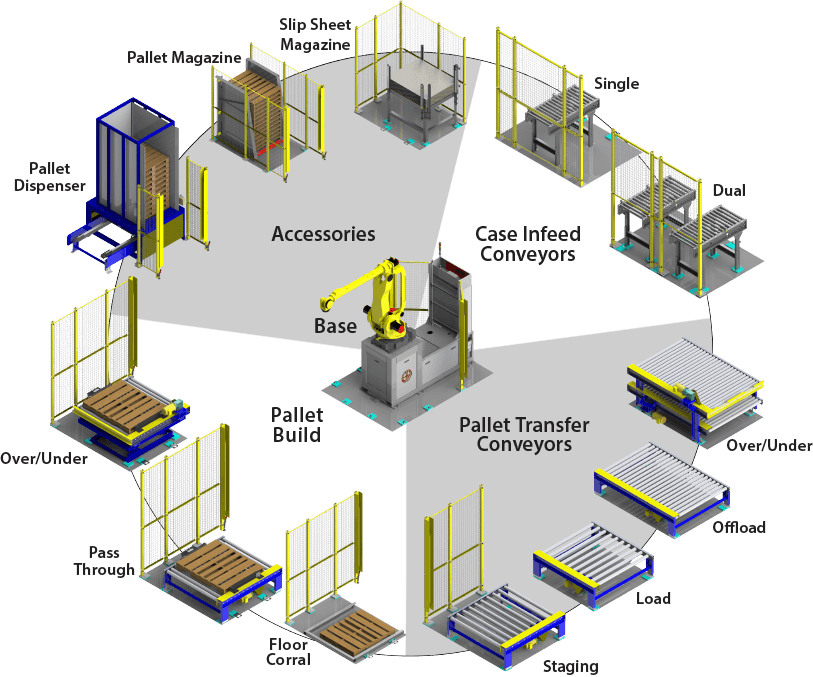

The interlocking pattern is a unique design as it allows for the system to be reconfigured and redeployed. Countless options are available with the modular mix and match designs.

We offer both FANUC R-1000 and FANUC M410 Robot options, powered by Rockwell controls.

APT’s pre-designed modular systems are intended for ease of build, maintenance, and operator use. Customers that purchase the APT-PAK systems save both engineering and programming cost.

We offer a FANUC 6 axis robot floor mounted or a FANUC Delta Style robot that is hung in our modular frame system.

Our systems use APT’s efficient and easy to use operator interface.