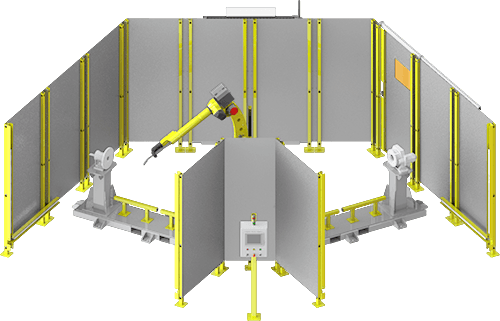

The headstock/tailstock weld cell is a versatile efficient set up for welding a wide array of long and large components.

MOD-WELD Head Stock Tail Stock

| Choose Your Power Supply | ||||||

|---|---|---|---|---|---|---|

| Fronius | Miller | |||||

| 400i | TPSi, air-cooled torch for welding steel. Includes PMC software. Comes with .035 wire feed rollers 3PH Power. Optional consumable or replacement parts up to 1/16 | 350C | Auto-Continuum™ 3PH or Auto-Deltaweld™ 1PH, air-cooled torch for welding steel. Comes with .035 wire feed rollers. Optional consumable or replacement parts up to 1/16 | |||

| 400i | TPSi, air-cooled torch for welding steel. Includes PMC software. Comes with .035 wire feed rollers 3PH Power. Optional consumable or replacement parts up to 1/16 | 350D | Auto-Continuum™ 3PH or Auto-Deltaweld™ 1PH, air-cooled torch for welding steel. Comes with .035 wire feed rollers. Optional consumable or replacement parts up to 1/16 | |||

| 400i-C | TPSi, cooler & water cooled torch.Includes PMC software. Comes with .035 wire feed rollers 3PH Power. Optional consumable or replacement parts up to 1/16 | 500C-CM | Auto-Continuum™ or Auto-Deltaweld™, cooler & water-cooled torch Comes with .035 wire feed rollers. 3PH Power. Optional consumable or replacement parts up to 1/16 | |||

| 500i-C | TPSi, cooler & water cooled torch.Includes PMC software. Comes with .035 wire feed rollers 3PH Power. Optional consumable or replacement parts up to 1/16 | 500D-CM | Auto-Continuum™ or Auto-Deltaweld™, cooler & water-cooled torch Comes with .035 wire feed rollers. 3PH Power. Optional consumable or replacement parts up to 1/16 | |||

| 400i-C-S | TPSi, cooler, water-cooled torch, push/pull CMT ready package for both steel (hard wire) & aluminum (soft wire). Includes PMC software. Equipped with 3/64 start-up consumables & drive wheels for aluminum welding. 3PH Power | 500C-C-S | Auto-Continuum™ 500, cooler, water-cooled FANUC Servo Torch to pull the wire. Equipped with 3/64 start-up consumables & drive wheels for aluminum welding. 3PH Power | |||

| 500i-C-S | TPSi, cooler, water-cooled torch, push/pull CMT ready package for both steel (hard wire) & aluminum (soft wire). Includes PMC software. Equipped with 3/64 start-up consumables & drive wheels for aluminum welding. 3PH Power | 500C-C-S | Auto-Continuum™ 500, cooler, water-cooled FANUC Servo Torch to pull the wire. Equipped with 3/64 start-up consumables & drive wheels for aluminum welding. 3PH Power | |||

| Tips & Tricks | Fronius TPS/i Tips & Tricks | Tips & Tricks | Miller Auto-Continuum™ Tips & Tricks | |||

| Available Training | Miller OpenBook | |||||

| Software Options | ||||||

| Fronius | ||||||

| LSC | Fronius Low Spatter Control, achieves high-quality weld seams with minimal spattering and increased deposition rate, as the LSC principle is based on the short circuit occurring at a low current level. This leads to soft reignition and a stable welding process. | |||||

| CMT | Fronius Cold Metal Transfer (CMT) welding, only available in CMT ready machines. Ideal for high performance welding in the areas of thin materials, brazing, visual aesthetics, cladding & WAAM welding consisting of all ranges of materials from Aluminums, Steels, Coppers, Titanium, & Nickel alloys | |||||

| FANUC | ||||||

| TPW | FANUC Thick Plate Weld Package is Touch Sensing & Through Arc Seam Track in one package. This robot/cobot software is available on both Fronius & Miller | |||||

Our standard MOD-WELD systems use APT’s efficient and easy to use operator interface.