- PLC & HMI Programming

- Sequence Based Programming

- PLC to Robot Integration

- Integration of Sensors & Devices

- Networking Communication

- Ethernet I/P

- Discrete

- Wireless

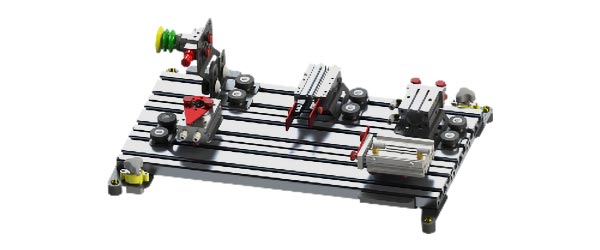

This PLC/HMI Trainer was developed for multiple learning experiences based on industry standards. The trainer has a template for the student to understand how ladder logic works before moving into programming. The trainer can then be connected via ethernet or wireless hub to communicate with other products including a FANUC robot.

This PLC/HMI Trainer was developed for multiple learning experiences based on industry standards. The trainer has a template for the student to understand how ladder logic works before moving into programming. The trainer can then be connected via ethernet or wireless hub to communicate with other products including a FANUC robot.

Also available to be purchased as a kit; the student will use industrial schematics to mount and wire all components with wire ferrules and labels.

This kit comes with all of the supplies needed to rebuild the PLC/HMI Trainer.

Includes:

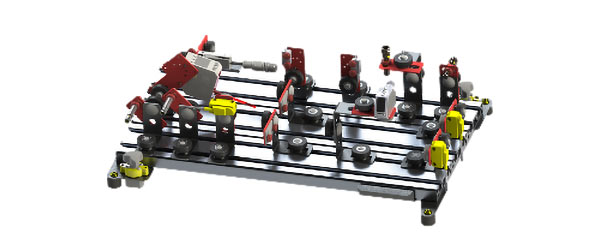

Sensors are used for detection of product, device location, color, etc. in industrial automation systems. The variety included allows for sensor type specific learning, operation and set up. The included brackets and hardware allow the sensors to be set up on a T-Slot tabletop plate in various scenarios.

Includes: Proximity, Optic, Hall Effect, Polarized Retro‑reflective, Smart Color, Test cylinder, Cord Sets.

Pneumatic fluid power devices are common in industrial automation systems. The variety included allows for motion, flow control, clamping, diverting, turning, vacuum generation, or moving of products and machinery items. The included brackets & hardware allow the cylinders to be set up on a T-Slot tabletop plate in various scenarios.

Includes: Actuators (Rotary, Guided linear, Parallel Gripper, Escapement), Venturi vacuum ejector, Vacuum cups

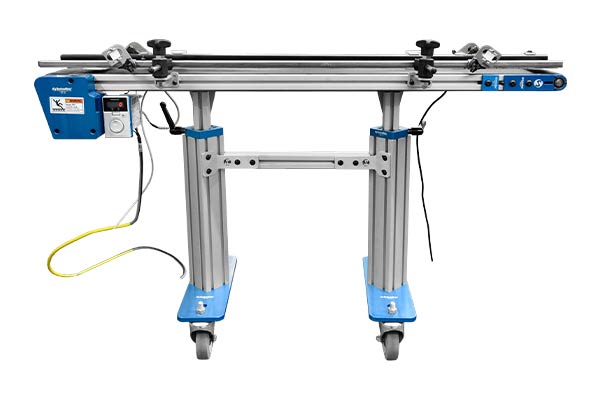

Free Standing Swivellink® 4-1/2”W X 36”L Variable Speed Conveyor. Conveyor overall height from the floor is adjustable from approximately 26” up to 35” off the floor.

Includes:

Tabletop Swivellink® 4-1/2”W X 36”L Variable Speed Conveyor. This conveyor can be placed on a flat surface. The conveyor overall height (top of belt) is approximately 6.75″ off the table.

Includes:

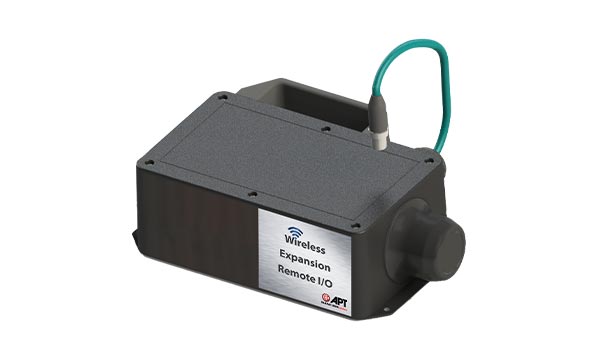

The wireless modules will expand the PLC Trainer and communicate with other items in your classroom

Includes: Configurable 16 points of input/output (using splitters on 8 access ports), Industry standard M12 5-pin port

Includes: WEP, WPA, and WPA2 security protocols, Anybus wireless bolt, Add network communication to your FANUC robot

Includes: 4 individually controllable valves, Double solenoid 2 position blocked center ports, open center ports, & detent. Single solenoid 2 position spring return.

Career Paths:

*FANUC Education Grant available for new Educational Institutes. Work with reseller to confirm details.

If purchased with a FANUC robot or FANUC CERT Cart then it would qualify for the Handling Tool CERT. If vision was added to the robot or CERT Cart then it would also qualify for iRVision. This PLC Trainer is a partnership between Rockwell, FANUC and APT Manufacturing Solutions.

Software

Rockwell Automation EDU Toolkit Bundle

Curriculum

Learning+ course content

Available through your local Rockwell distributor.

Weld CERT Cart