- Robot/Cobot Programming

- Robot to CNC integration

- 2D Vision Guidance

- CNC Mill & Lathe Programming

- G-Codes & M-Codes

- Speeds & Feeds

- Automated Fixturing

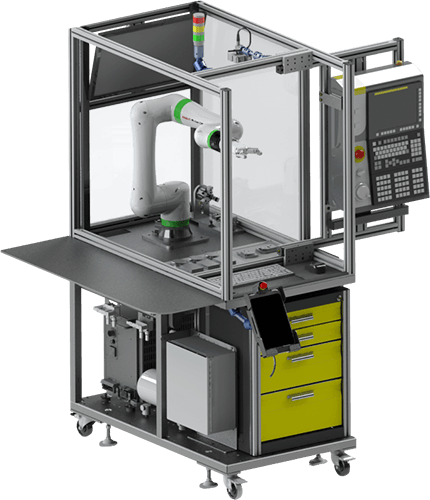

This compact and mobile equipment allows you to teach CNC and robotics in a classroom environment. Students will discover that while the Robot and CNC each have distinct roles, they communicate effectively to collaborate. Additionally, by using the optional iRVision, they will learn 2D guided robot motion & part inspection.

This compact and mobile equipment allows you to teach CNC and robotics in a classroom environment. Students will discover that while the Robot and CNC each have distinct roles, they communicate effectively to collaborate. Additionally, by using the optional iRVision, they will learn 2D guided robot motion & part inspection.

FANUC LR Mate ER-4iA robot

FANUC CRX-5iA cobot

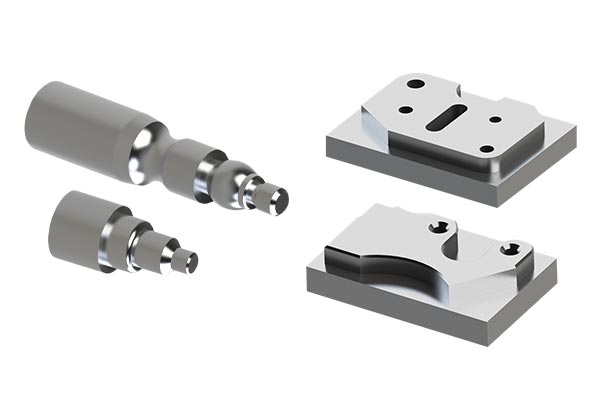

Pick and place material for either mill or lathe to load and unload by the robot from a template or vision picking area (optional robot guided vision).

Includes: Pick & place material for both mill & lathe simulated machining.

FANUC’s fully integrated visual detection system that enables robots to see. As a result, production flexibility increases because expensive positioning fixtures are not required. 2D vision is suited for any material handling application including palletizing & depalletizing, as well as vision inspection.

Career Paths:

NOCTI Certifications:

FANUC Robotics Courses:

CNC Concepts Courses:

APT Integration Courses:

*FANUC Education Grant available for new Educational Institutes. Work with reseller to confirm details.

Material Handling (MH) CERT Instructor Training and Tool Kit

Material Handling (MH) CERT School Comprehensive Educational Package

Weld CERT Cart