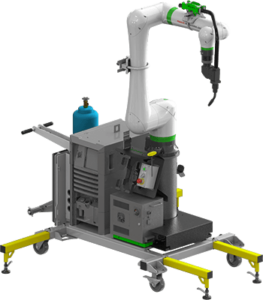

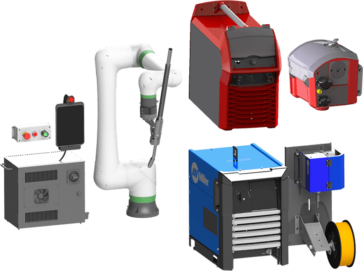

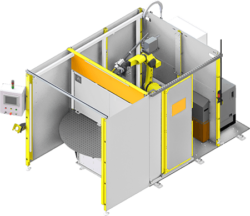

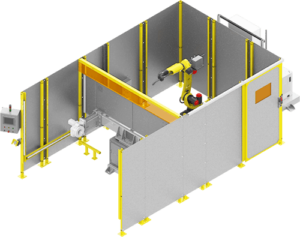

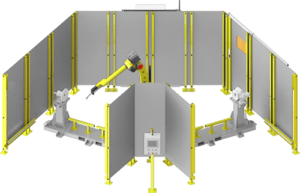

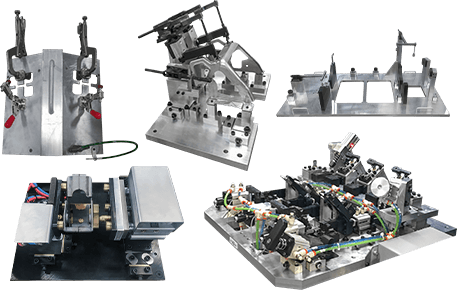

- FANUC Robot / Rockwell Controls / Choice of Miller Electric or Fronius power source / Integrated by APT Manufacturing

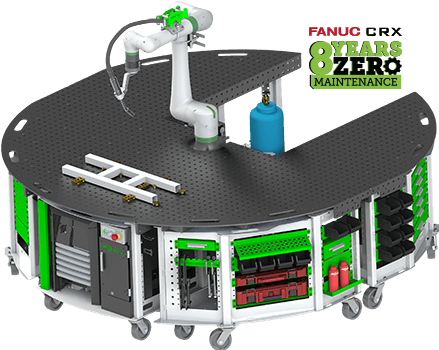

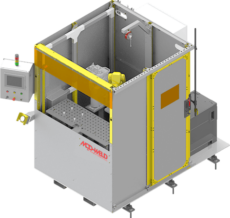

- Load/Unload directly into the weld cell

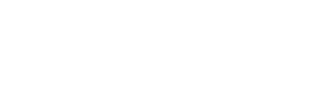

- Locating holes for Fixtures to be removed and set back up in same location

- Ease of set up

- Easy maintenance and cleanliness

- Side access door for entering in a safe environment

- Small footprint

- Recipe Management with room for up to 100 recipes

- Base model is configured to weld steel (hard metal), soft metals require additional options

Menu