Menu

- wrapper

- Robotic Palletizing

- Robotic Cutting & Welding

- Industrial Education Solutions

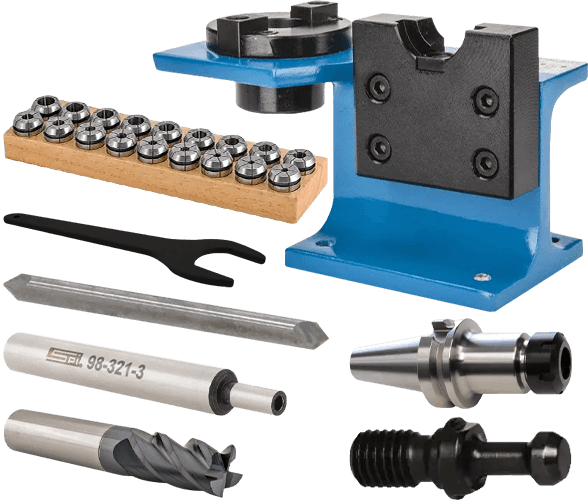

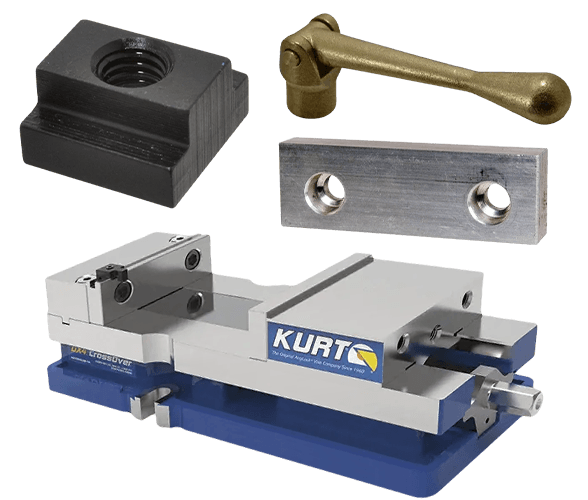

FANUC ROBODRILL α-D14MiB5

FANUC Courses:

CNC Concepts Courses:

Career Paths:

NIMS Certifications:

Clock & Business Card Holder

*ROBODRILL 5-axis available with custom order

Weld CERT Cart