Menu

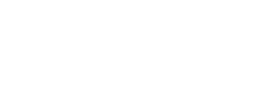

The CSM was developed between FANUC America, APT Manufacturing, Rockwell Automation, and listening to the industry’s demands for employability skills today and what education needs to deliver this type of technology for preparing students for a smoother transition from education to industry on the first day.

The entire system addresses three common denominators in manufacturing: automation, process control, and data analytics; these skill sets are required to enter manufacturing at all levels. The modular design allows you to use this within your classroom and is offered for purchase as a set or to individually grow with your program. The integrated system was designed around the FANUC CERT program and teaches foundational skills in robotic operator and technician credentials, which is industry-recognized, and with Rockwell Automation and other channel partners, this makes up a complete certification system for 4.0.

FANUC Robotics Courses:

CNC Concepts Courses:

Rockwell Automation Courses:

APT Integration Courses:

Career Paths:

NOCTI Certifications:

NIMS Certifications:

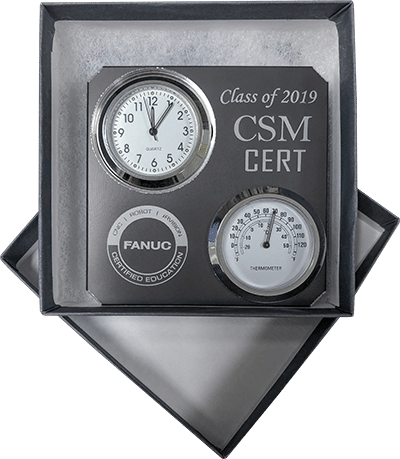

FANUC-Rockwell Certifications:

Material Handling (MH) CERT Instructor Training and Toolkit:

Material Handling (MH) CERT School Comprehensive Educational Package:

CNC:

*FANUC Education Grant available for new Educational Institutes. Work with reseller to confirm details.

Software

Rockwell Automation EDU Toolkit Bundle

Curriculum

Learning+ course content

Available through your local Rockwell distributor.

This system is truly like no other Industrial System for Education Institutions.

Your students will use FANUC/Rockwell products on a factory system to understand a fully integrated line. Each cart can also be detached for individual learning.

Integration from:

Robot Options Include:

FANUC’s new robot controllers feature the new iPendant with enhanced screen resolution and processing capability. The new user interface, iHMI, can display guides for setup and programming, as well as tutorials from the main home page which has a design common to FANUC CNCs, enabling easier use of robots.

Using the programming guide, even first-time robot users can create a program for a simple handling task and execute it in just 30 minutes! Easier usage also improves efficiency by facilitating system setup and maintenance.

High-Performance Vertical Machining Center α-D14MiB(5)

The ultimate all-round vertical machining center

Model M, perfect for milling and drilling tasks requiring maximum precision, versatility and reliability.

See FANUC’s ROBODRILL Brochure

(not all features included with the education package)